- Overview

- Recommended Products

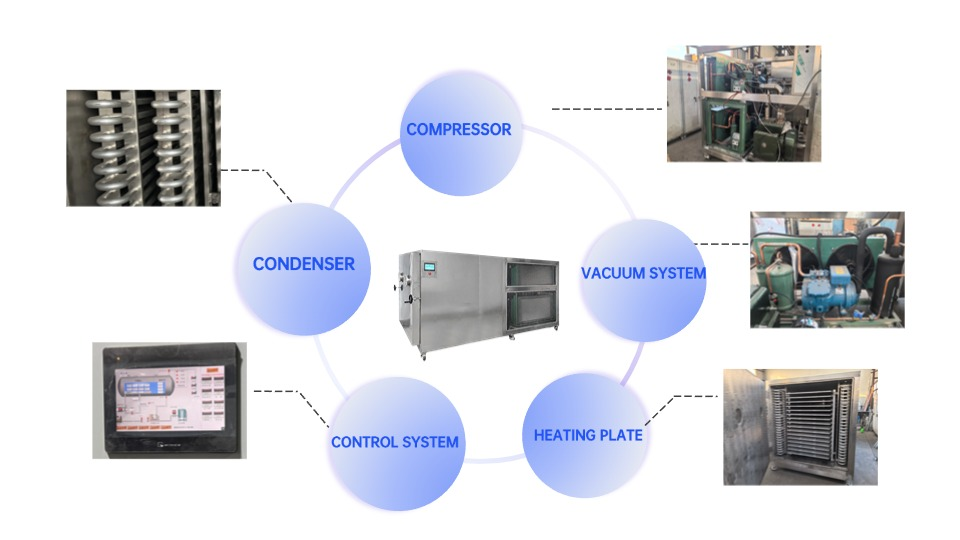

FREEZING DRYING PROCESS

Freeze drying process, also known as lyophilization or sublimation, consists of two main stages. Initially fresh cut products are transported in to so called “Blast Freezer” and frozen below -40C temperature. Once products are deeply frozen, they are put into freeze drying chamber where vacuum is created by lowering the air pressure at certain degree.

Afterwards low temperature heat is transferred to products through the shelves of the freeze-drying chamber and ice in the product becomes gas bypassing liquid phase. Freeze-dried fruit contains all the nutritional benefits of fresh fruit and only water has been removed, and replaced with crunch. All our freeze dried products are in sealed package and has a long shelf life.

| NO | ITEM | PARAMETERS |

| 1 | Model | FD-20 |

| 2 | Freeze drying area | 20m³ |

| 3 | Whole size | 4200*1700*1850mm |

| 4 | Weight | 4500kg |

| 5 | Power | 39kw /380V/50Hz |

| 6 | Heating plates temperature Range | Normal Temperature ~+95℃ |

| 7 | Capture water Capacity | 300kg/batch |

| 8 | Power consumption | 25-39kw/h |

| 9 | Structure | All-in -one |

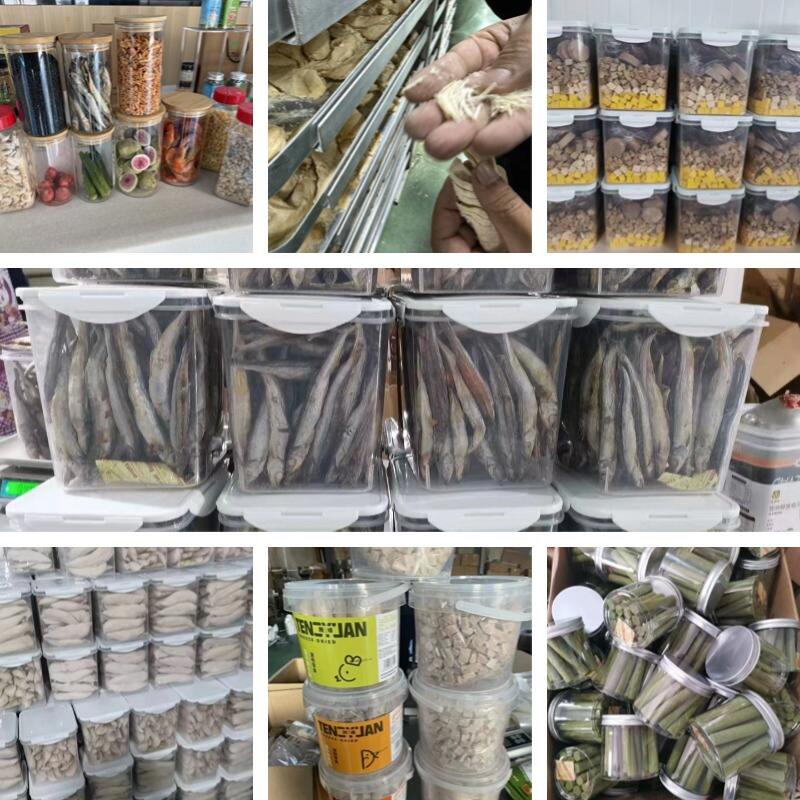

PRODUCTS BEING FREEZE DRIED

·Camping Food ·Meats

·Pet Food ·Fish

·Coffee ·Ice Cream

·Mushrooms ·Eggs

·Guacamole/Salsa ·Baby Food

·Herbs ·Easy-to-make Meals

·Fruits & Veggies·Soups ·Cannabis & Related Products

Description

Product Overview

The 20㎡ freeze dryer is an industrial-scale lyophilization system designed for pilot-to-production applications, preventing cross-contamination. With a batch capacity of 400-500kg (depending on material density), it is ideal for biopharmaceuticals, food processing, and advanced materials

Key Specifications

1.Freeze-Drying Area: 20㎡

2.Condenser Temperature: ≤-75°C (cascade refrigeration, ice capture ≥40kg/24h)

3.Shelf Temperature Range: -55°C to +80°C (silicone oil heating, ±1°C uniformity, 50 programmable segments)

4.Vacuum System: Ultimate vacuum ≤5Pa (empty), evacuation time <30 mins (to 10Pa)

5.Smart Control: 7-inch industrial touchscreen with data export, remote monitoring, and programmable curves

Core Features

Energy Efficiency: Modular cooling with heat recovery reduces energy consumption by 15%

Compliance: GMP-compliant, supports CIP/SIP cleaning and sterilization

Applications

Food Industry: Preservation of fruits, coffee, and meat with original nutrients and color

Freeze Drying Process

Freeze drying process, also known as lyophilization or sublimation, consists of two main stages. Initially fresh cut products are transported in to so called “Blast Freezer” and frozen below -40C temperature. Once products are deeply frozen, they are put into freeze drying chamber where vacuum is created by lowering the air pressure at certain degree.

Afterwards low temperature heat is transferred to products through the shelves of the freeze-drying chamber and ice in the product becomes gas bypassing liquid phase. Freeze-dried fruit contains all the nutritional benefits of fresh fruit and only water has been removed, and replaced with crunch. All our freeze dried products are in sealed package and has a long shelf life.