200㎡ Industrial Freeze Dryer Lyophilizer - 3000kg/Batch, 304 SS Auto Touch Screen for fruit/Food/Seafood (FDA/CE)

- Overview

- Recommended Products

FREEZING DRYING PROCESS

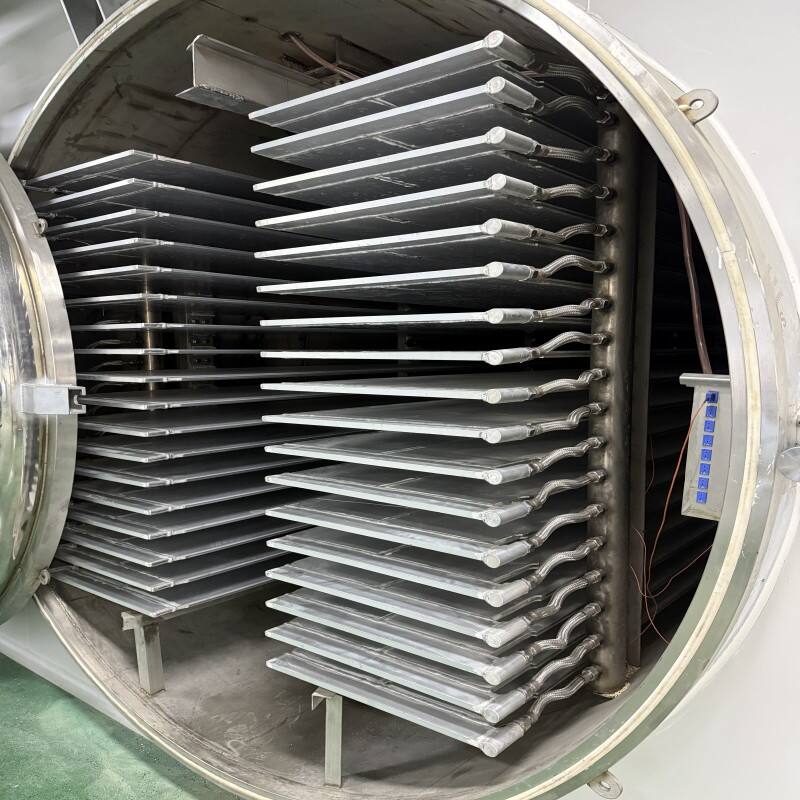

Freeze drying process, also known as lyophilization or sublimation, consists of two main stages. Initially fresh cut products are transported in to so called “Blast Freezer” and frozen below -40C temperature. Once products are deeply frozen, they are put into freeze drying chamber where vacuum is created by lowering the air pressure at certain degree.

Afterwards low temperature heat is transferred to products through the shelves of the freeze-drying chamber and ice in the product becomes gas bypassing liquid phase. Freeze-dried fruit contains all the nutritional benefits of fresh fruit and only water has been removed, and replaced with crunch. All our freeze dried products are in sealed package and has a long shelf life.

| NO | ITEM | PARAMETERS |

| 1 | Model | FD-10 |

| 2 | Freeze drying area | 10m³ |

| 3 | Whole size | 3700*1400*1800mm |

| 4 | Weight | 3000kg |

| 5 | Power | 25kw/380V/50Hz |

| 6 | Heating plates temperature Range | Normal Temperature ~+95℃ |

| 7 | Capture water Capacity | 120kg/batch |

| 8 | Power consumption | 12kw/h |

| 9 | Structure | All-in -one |

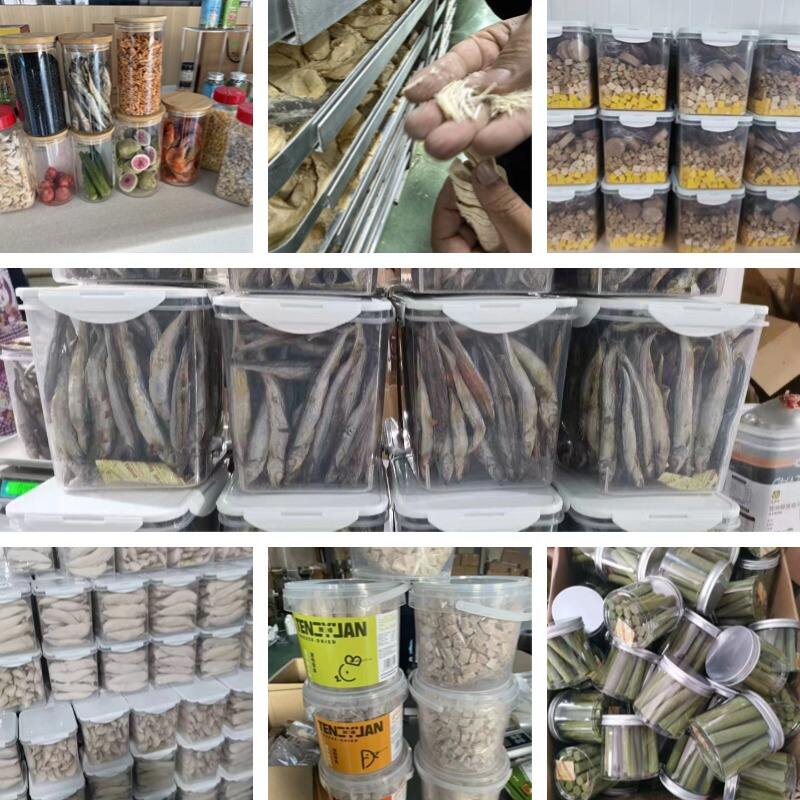

PRODUCTS BEING FREEZE DRIED

·Camping Food ·Meats

·Pet Food ·Fish

·Coffee ·Ice Cream

·Mushrooms ·Eggs

·Guacamole/Salsa ·Baby Food

·Herbs ·Easy-to-make Meals

·Fruits & Veggies·Soups ·Cannabis & Related Products

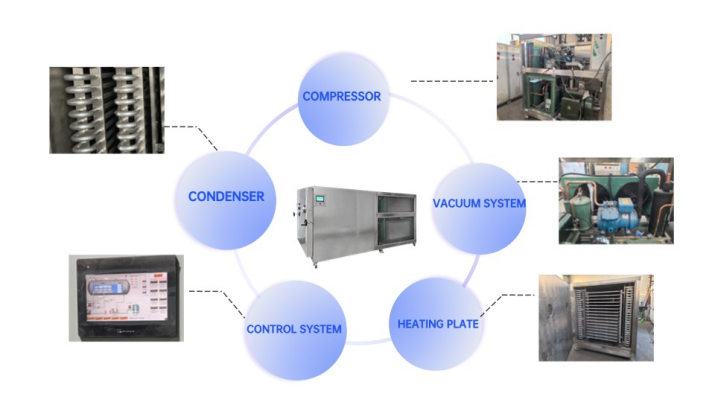

Working principle

Freeze Drying Process

Freeze drying process, also known as lyophilization or sublimation, consists of two main stages. Initially fresh cut products are transported in to so called “Blast Freezer” and frozen below -40C temperature. Once products are deeply frozen, they are put into freeze drying chamber where vacuum is created by lowering the air pressure at certain degree.

Afterwards low temperature heat is transferred to products through the shelves of the freeze-drying chamber and ice in the product becomes gas bypassing liquid phase. Freeze-dried fruit contains all the nutritional benefits of fresh fruit and only water has been removed, and replaced with crunch. All our freeze dried products are in sealed package and has a long shelf life.

Product Overview

The 200㎡ food freeze dryer is an industrial-scale lyophilization system designed for large-batch food processing, featuring integrated in-situ processing to eliminate cross-contamination. With a batch capacity of 2000–4000kg, it is optimized for instant beverages (coffee, tea powder), fruit crisps, pet food, and high-value seafood preservation.

Key Specifications

| Parameter | Typical Range | Technical Notes |

| Freeze-Drying Area | 197–200㎡ | Customizable shelf layout |

| Condenser Temp | ≤-65°C to -70°C (empty) | Cascade refrigeration, ≥90% vapor trapping efficiency |

| Ice Capture | 2400–4000kg/batch | Split condenser, defrosting ≤90 mins (spray/immersion) |

| Shelf Temp Range | -45°C to +120°C | Silicone oil heating, ±1°C uniformity, 50 programmable segments |

| Ultimate Vacuum | ≤2.7–10Pa (empty) | Dual vacuum pumps, evacuation time ≤30 mins |

| Power Consumption | 174–570kW (40% saving with VFD) | Variable-frequency drives + heat recovery |

| Shelf Configuration | (15+1) layers × 2 sets | 304 stainless steel, adjustable spacing (70–80mm) |

| Drying Cycle | 18–24 hrs/batch | 3–4 batches/day in continuous mode |

Core Technical Features

Energy-Efficient Design

1.Split Condenser:Captures 3000–4000kg/batch ice, defrosting ≤90 mins, reducing cycle time by 30%

2.VFD Heat Recovery:Cascade refrigeration with waste heat reuse cuts energy by 15–40%

Intelligent Control

1.Programmable Process:50-segment temperature curves, ≥32 recipe storage, 50ms data sampling (HACCP-compatible

2.Oxidation Prevention:Auto inert gas (N₂/Ar) backfilling upon vacuum failure

Food-Specific Engineering

1.Wide Temperature Range:-45°C to +120°C adapts to fruits, meats, coffee, etc

2.CIP Cleaning:Rotating nozzles cover dead zones, rinse water meets food-grade standards

Industrial Adaptability

1.Continuous Production:Isolated condenser enables pre-freezing → drying → unloading pipeline

2.Cleanroom Interface:Full-opening or automatic "pizza door" minimizes contamination risk

Primary Applications & Benefits

| Field | Typical Use Cases | Key Advantages |

| Instant Beverages | Coffee, tea powder, juice | ≥98% flavor retention, instant solubility (≤15s rehydration) |

| Fruit Crisps | Strawberry, mango, mushroom | ≥95% color/vitamin retention, 5x shelf-life (vs. hot-air drying) |

| Pet Food | Freeze-dried raw meat, additives | Preserves protein activity, no preservatives |

| Seafood Processing | Shrimp, scallops, fish fillets | Maintains texture, ≥90% rehydration rate |