- Overview

- Recommended Products

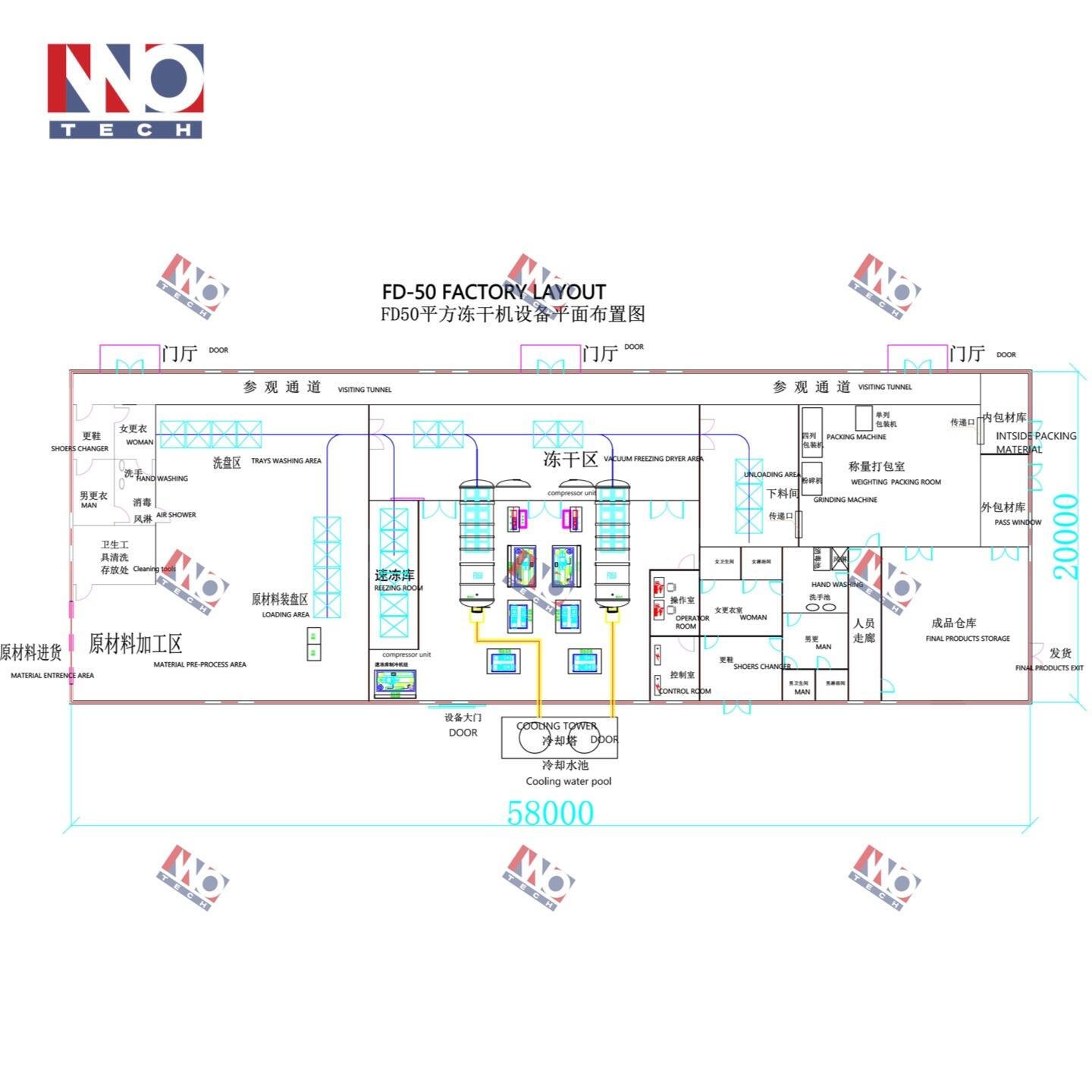

Specifications:

| (Key Specifications) | (Details) |

| (Model) | FD-100 (100 m² Industrial-grade |

| (Loading Capacity) | 1200-1500kg (Fresh Strawberries) |

| (Ice Capacity) | 1200-1300kg |

| (Heating Temp) | Ambient Temperature ~ +95℃ (Dual-sided Radiant Heating |

| (Cold Trap Temp) | ≤ -55℃ |

| (Energy Consumption) | 90kw/h (High-efficiency and Energy-saving Mode |

| (Tray Size) | 610×610×35mm (Standard Industrial Dimensions |

Description:

FD-100 industrial mango freeze dryer with 100 square meter shelf area

Industrial 100㎡ Mango Freeze Drying Line: Preserve the Essence of the Tropics

Our FD - 100 vacuum freeze dryer is optimized for high - sugar tropical fruits like Nam Dok Mai and Alphonso mangoes. By using advanced lyophilization technology, we transform fresh mangoes into premium, crispy snacks while retaining 95% of their original nutrients and vibrant golden color.

● Processing Capacity

Single batch handles 1200 - 1500kg of fresh mangoes, yielding approximately 180 - 220kg of high - quality freeze - dried slices.

● Color & Flavor Locking

Our - 40℃ flash freezing and high - vacuum sublimation process prevent browning and preserve the natural sweetness and fiber texture of the mango.

● Precision Temperature Control

Shelf heating ranges from ambient to +95℃, ensuring even drying of thick mango slices without caramelization.

Industrial FD-100 freeze drying chamber with premium freeze-dried mango slices and production line overview.

Applications

High-quality freeze-dried mango slices with natural golden color processed by industrial vacuum lyophilization technology.

● Premium Mango Snacks:Production of 100%natural,additive-free whole or sliced mango crisps for health-conscious markets.

Baking&Confectionery:Mango dices and powders for cake decoration,premium chocolates,and artisanal bread.

Breakfast&Cereals:Perfect for mixing with yogurt,oatmeal,and trail mixes to add a tropical flavor.

● +1

Beverage Ingredients:Quickly rehydrating mango pieces for fruit teas and nutritional smoothies

Our Advantages:

Transformation process from fresh sliced mango to premium crispy freeze-dried mango chips using vacuum lyophilization.

● Dual-Side Radiant Heating:Mangoes have high sugar content;our radiant heating ensures uniform dehydration,preventing"wet centers"in thicker slices.

● High Ice Condenser Capacity:With a 1200-1300kg ice-catching capacity,the system handles the high moisture content of fresh mangoes efficiently.

● Energy Efficient:Actual power consumption is only 90kw/h,significantly lowering the cost per kg of dried mango.

● GMP&Food Safety:Entire production line follows GB 17325-2015 standards,ensuring your mango products meet international export requirements

Frequently Asked Questions

Q: What is the drying cycle for mangoes on the FD-100?

A: Mangoes typically take 20-24 hours due to their fiber and sugar density. This includes 12-14 hours of sublimation and 6-8 hours of desorption to reach a final moisture content of ≤3%.

Q: Can this machine handle different mango varieties?

A: Yes, the Siemens PLC system allows for customized recipes for slices, dices, or purees, adjusting heating curves to suit different sugar levels.

Q: How do you support overseas mango processing plants?

A: We offer turnkey solutions including onsite installation, 5-day multilingual training, and a 3-year global warranty on core components supported by our warehouses in the USA and Germany