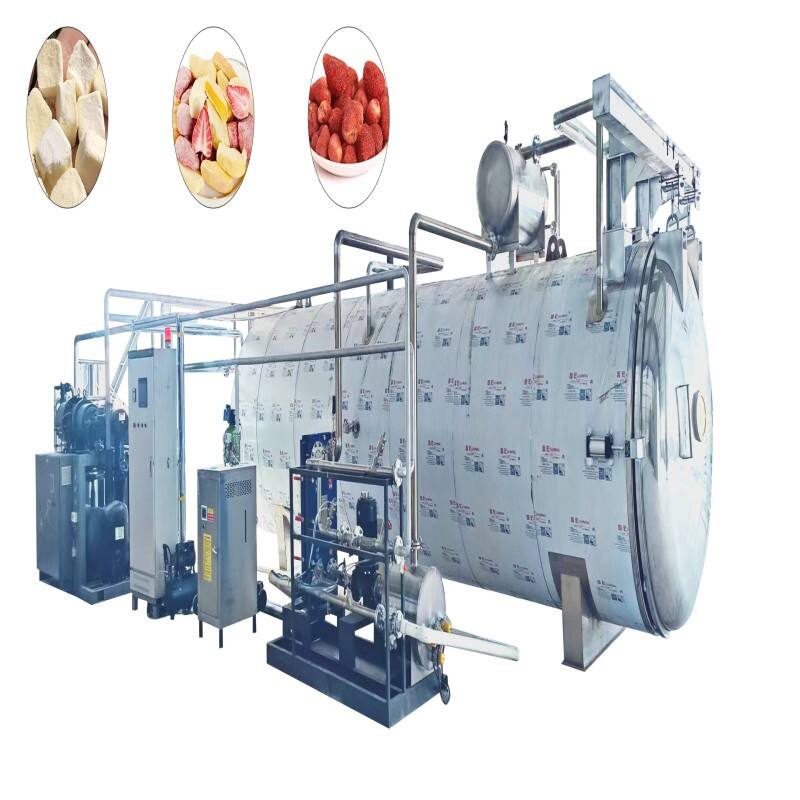

เครื่องทำแห้งเย็นแช่แข็ง

เครื่องแห้งแข็ง หรือเรียกอีกชื่อว่า lyophilizer เป็นวิธีการแก้ไขทางเทคโนโลยีที่พัฒนาขึ้น ซึ่งกําจัดความชื้นจากวัสดุผ่านกระบวนการ sublimation เครื่องมือที่มีความซับซ้อนนี้ทํางานโดยการแข็งสินค้าก่อน จากนั้นลดความดันและเพิ่มความร้อน เพื่อให้น้ําแข็งเปลี่ยนจากของแข็งเป็นก๊าซโดยตรง เครื่องประกอบด้วยส่วนประกอบสําคัญหลายส่วนรวมถึงห้องว่าง, เครื่องปรับความร้อน, ระบบเย็น และหน่วยควบคุม เครื่องจักรเหล่านี้ทํางานในอุณหภูมิต่ําถึง -50 °C ถึง -80 °C สามารถประมวลผลวัสดุต่างๆ ได้แก่ ผลิตภัณฑ์อาหาร ยา และตัวอย่างชีววิทยา เทคโนโลยีนี้รักษาโครงสร้างเดิม รูปแบบและสารอาหารของผลิตภัณฑ์ และขยายอายุการใช้งานของมันให้นานขึ้นอย่างมาก เครื่องจักรแห้งแข็งสมัยใหม่มีเครื่องควบคุมอัตโนมัติ เครื่องตรวจวัดอุณหภูมิหลายเครื่อง และระบบบริหารระยะว่างที่แม่นยํา เพื่อให้เกิดสภาพการแปรรูปที่ดีที่สุด มันมีขนาดต่าง ๆ ตั้งแต่เครื่องมือบนเบนจ์สําหรับการใช้ในห้องปฏิบัติการ ไปจนถึงระบบขนาดอุตสาหกรรม ที่สามารถประมวลผลวัสดุได้หลายร้อยกิโลกรัม กระบวนการโดยทั่วไปมี 4 ขั้นตอน: การนําไปแข็งก่อน การแห้งเป็นต้นไป การแห้งเป็นรอง และการบรรจุสุดท้าย ทั้งหมดนี้ถูกดําเนินการในสภาพแวดล้อมที่ควบคุมเพื่อรักษาความสมบูรณ์ของผลิตภัณฑ์