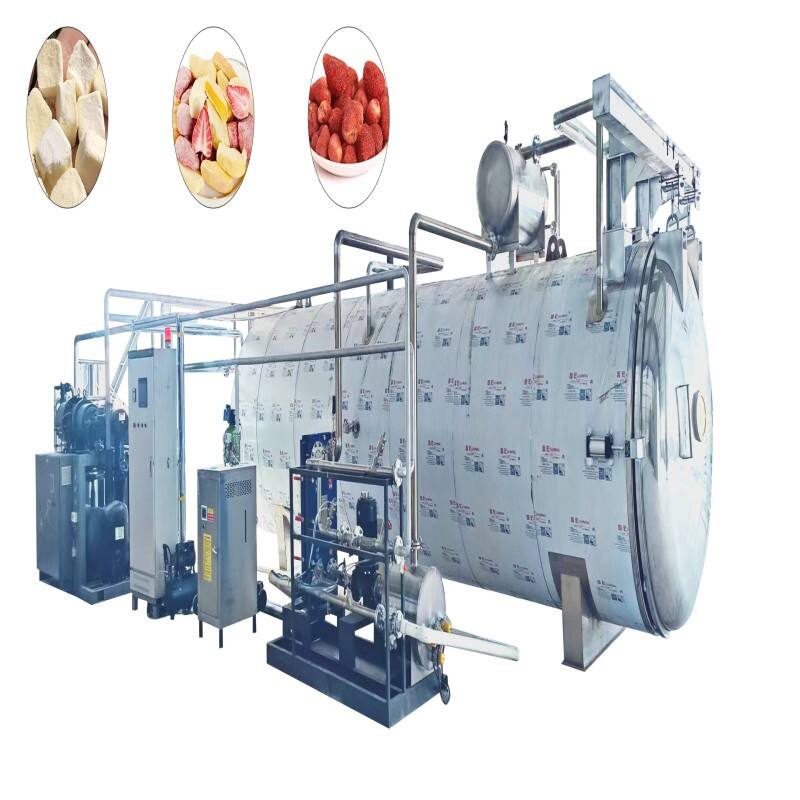

frozen dry machine

A frozen dry machine, also known as a lyophilizer, is an advanced technological solution that removes moisture from materials through the process of sublimation. This sophisticated equipment operates by freezing the product first, then reducing pressure and adding heat to allow frozen water to change directly from solid to gas. The machine consists of several key components including a vacuum chamber, condenser, refrigeration system, and control unit. Operating at temperatures as low as -50°C to -80°C, these machines can process various materials including food products, pharmaceuticals, and biological samples. The technology preserves the original structure, appearance, and nutritional content of products while extending their shelf life significantly. Modern frozen dry machines incorporate automated controls, multiple temperature sensors, and precise vacuum management systems to ensure optimal processing conditions. They come in various sizes, from benchtop units for laboratory use to industrial-scale systems capable of processing hundreds of kilograms of material. The process typically involves four stages: pre-freezing, primary drying, secondary drying, and final packaging, all conducted in a controlled environment to maintain product integrity.