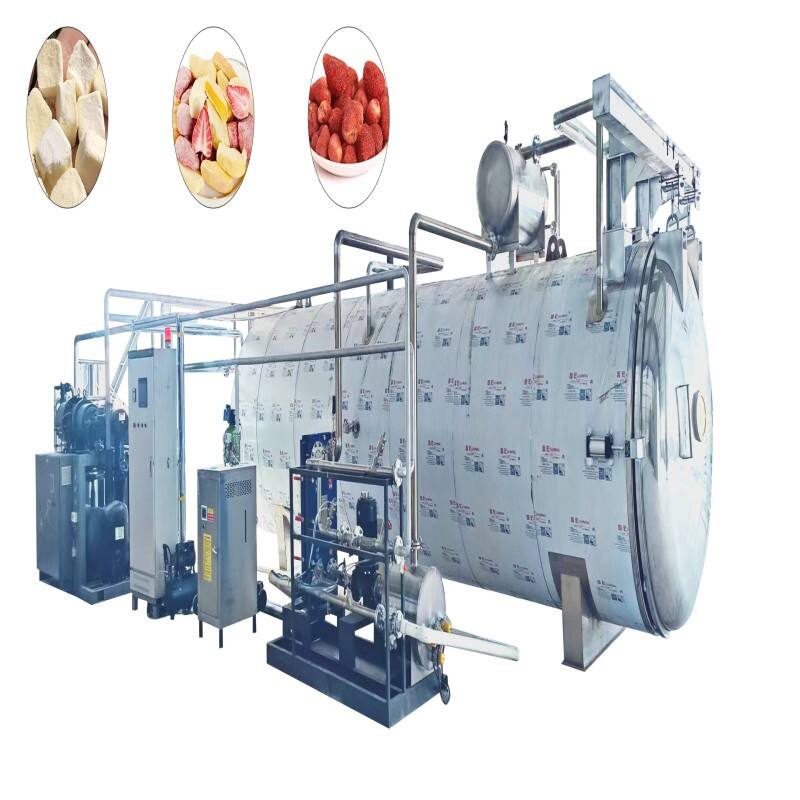

best freeze drying machine

The best freeze drying machine represents cutting-edge preservation technology, offering unparalleled performance in maintaining food quality and extending shelf life. This advanced system operates through a sophisticated four-stage process: pre-freezing, primary drying (sublimation), secondary drying (desorption), and sealing. The machine features precise temperature control systems ranging from -50°C to +30°C, enabling optimal preservation of various products. Its state-of-the-art vacuum system maintains pressure levels below 10 Pa, ensuring efficient moisture removal while preserving the product's original structure. The unit comes equipped with smart sensors that continuously monitor and adjust processing parameters, guaranteeing consistent results. With a spacious chamber design accommodating multiple trays, the machine offers efficient batch processing capabilities. The user-friendly touch-screen interface provides real-time monitoring and easy operation, while the advanced PLC control system ensures precise automation of the entire process. This freeze drying machine excels in preserving pharmaceuticals, food products, biological materials, and other sensitive items, maintaining their original properties, including taste, texture, and nutritional value.