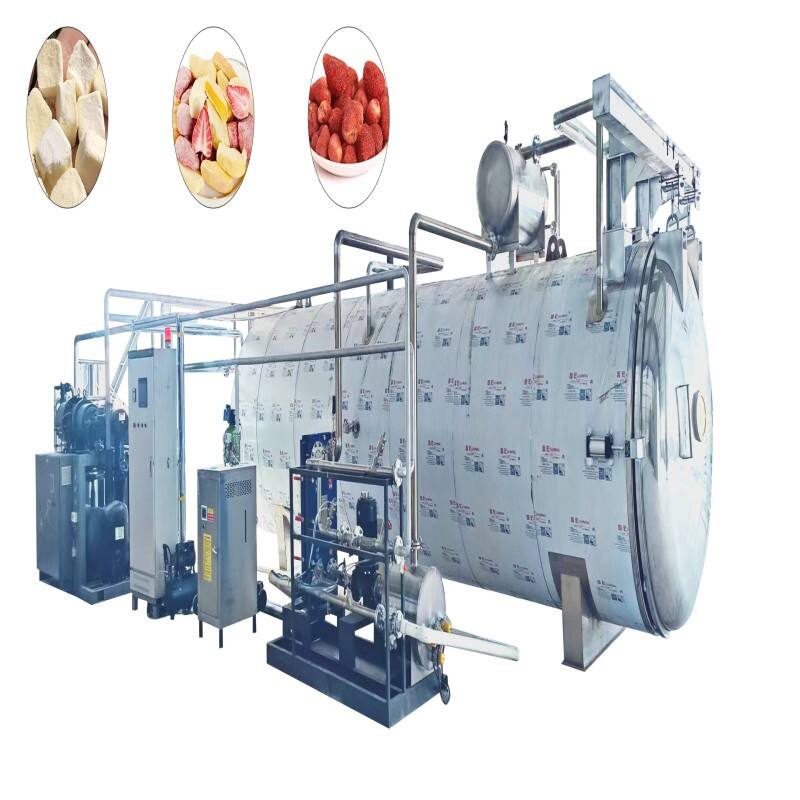

freeze drying machine price

The freeze drying machine price represents a significant investment in advanced food preservation and pharmaceutical processing technology. These sophisticated systems, available across various price points from $5,000 to $50,000 for industrial models, incorporate state-of-the-art freeze drying technology that removes moisture from products while preserving their essential characteristics. The pricing structure typically reflects the machine's capacity, ranging from small laboratory units to large industrial installations. Modern freeze drying machines feature precise temperature control systems, advanced vacuum technology, and programmable interfaces that ensure consistent results. The price often includes essential components such as vacuum pumps, condensers, and heating elements, all working in harmony to achieve optimal freeze drying results. These machines find extensive applications in food processing, pharmaceutical manufacturing, and biotechnology sectors, where the preservation of product integrity is paramount. The investment in a freeze drying machine is justified by its ability to extend product shelf life significantly, maintain nutritional value, and preserve the original structure of processed materials. The price point also factors in additional features such as automated controls, data logging capabilities, and energy-efficient operations.