[Cross-border cooperation milestone]

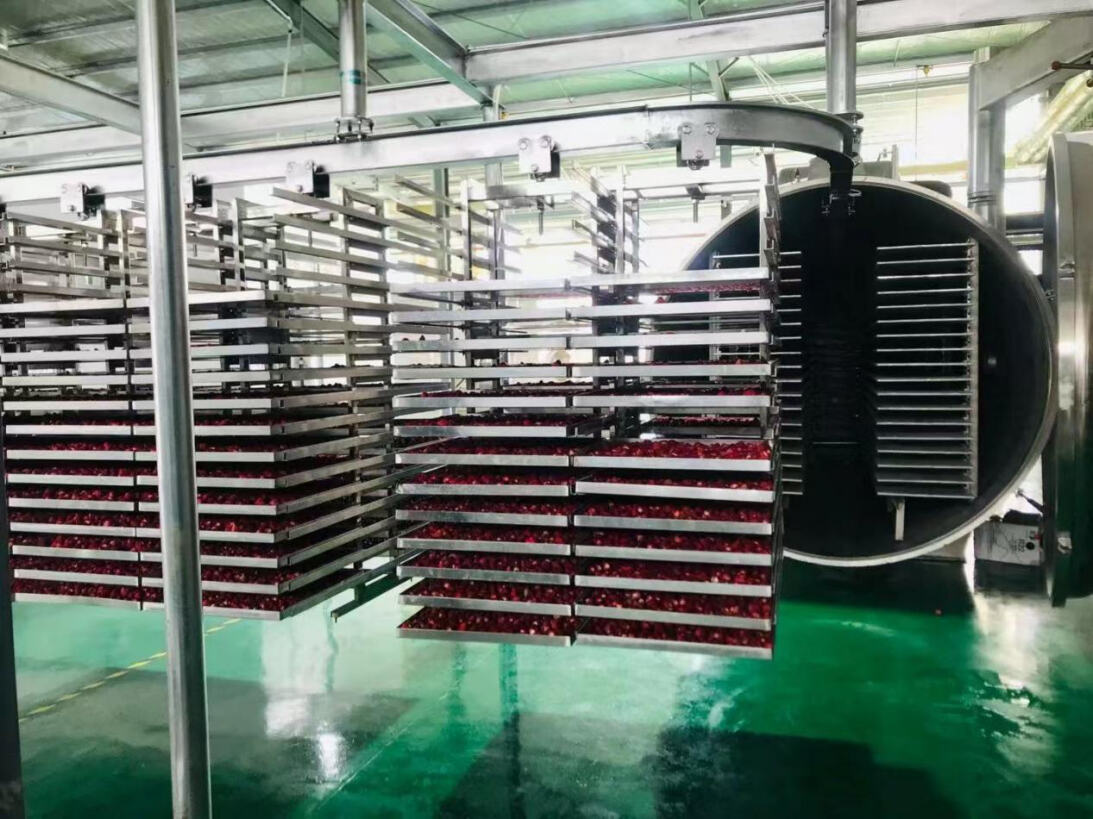

In the wave of intelligent upgrading of the global food processing industry, Zhucheng Yinuo Machinery Co., Ltd. (hereinafter referred to as "Yinuo Machinery") has successfully reached a strategic cooperation with a leading food company in Vietnam with its hard-core technology and excellent service, and tailored an intelligent vacuum freeze-drying production line for its newly built benchmark fruit and vegetable processing base in Southeast Asia. Cutting-edge technological breakthroughs reshape freeze-drying industry standards Targeted overcoming tropical fruit processing problems Southeast Asia's rich tropical fruit resources are prone to sugar caramelization and nutrient loss during the freeze-drying process due to their high sugar and high water content. After two years of technical research, the Yinuo Machinery R&D team has innovatively launched the "ultra-low temperature molecular fresh-locking freeze-drying system". The system is equipped with a self-developed intelligent gradient pre-freezing algorithm**. Through millisecond-level temperature control in an ultra-low temperature environment of -45℃, the ice crystal formation rate is precisely controlled, and the freeze-drying time of pineapple chips is greatly compressed from the industry average of 12 hours to 8 hours. At the same time, more than 98% of the vitamins, anthocyanins and other nutrients in the fruit are completely retained, and the fruit rehydration rate is increased to 95%, far exceeding the international standards of similar equipment. This technology has won a number of national invention patents and has passed the EU CE certification and strict testing by local authorities.

Full-process intelligent monitoring to ensure production stability

The production line is equipped with the AIoT intelligent monitoring platform independently developed by Yinuo Machinery, which integrates 32 sensors to monitor 28 core parameters such as pressure, temperature, and humidity in the freeze-drying chamber in real time, and automatically optimizes the freeze-drying curve through machine learning algorithms. When abnormal fluctuations are detected, the system can trigger an early warning within 0.1 seconds, and intelligently match a variety of emergency plans to ensure zero failures throughout the production process and zero defects in product quality.

Full-cycle service system, creating a model of international cooperation

Localized service network with deep coverage

In order to completely eliminate the worries of international customers, Yinuo Machinery has built a "three-in-one" service system in Vietnam: set up a large spare parts warehouse, reserve more than a thousand spare parts including freeze dryer core components, and achieve 24-hour rapid response for most repair parts; set up a bilingual technical team composed of Chinese experts and local engineers to provide 7×24 hours remote diagnosis and on-site services; develop a guidance system, customers can get maintenance tutorials through mobile phones, and the maintenance efficiency is increased by 60%.

Full-chain compliance support, accelerate project implementation

Yinuo Machinery relies on rich international certification experience to provide one-stop compliance services from equipment design to certification declaration for cooperative enterprises. In response to the strict access standards in the international and Southeast Asian regions, the company's technical team spent several months to complete more than 100 technical parameter optimizations, assisting customers to successfully pass the certification review, and shortening the overall project production cycle by 3 months, providing strong support for enterprises to seize market opportunities.