การทำแห้งแบบแช่แข็งด้วยห้องสุญญากาศ

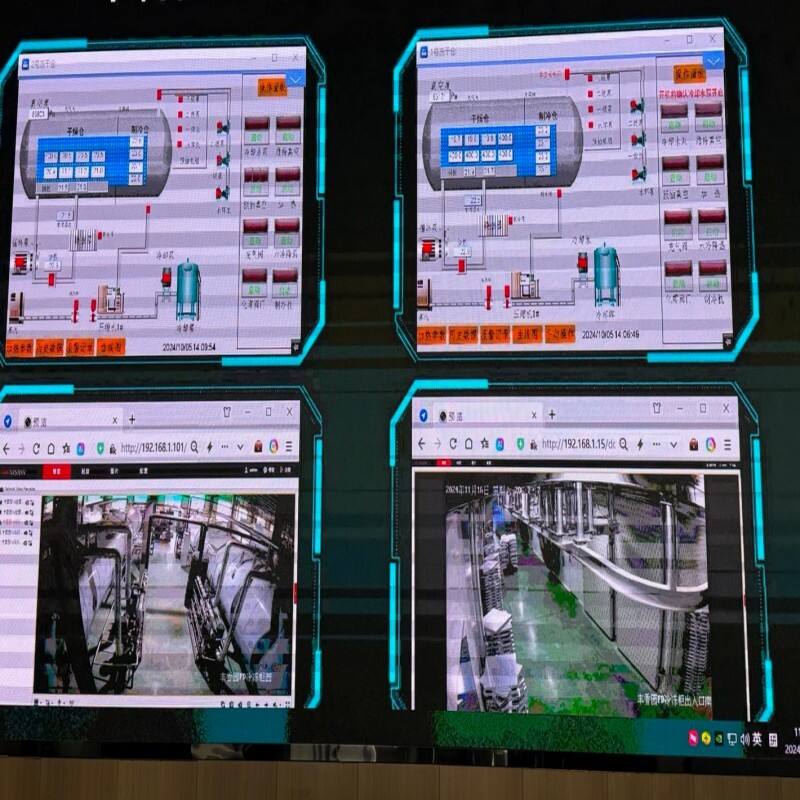

การแห้งแบบต้มเย็นด้วยห้องว่างเป็นเทคโนโลยีรักษาที่ซับฟิสิเคชั่น ซึ่งรวมหลักการของการ sublimation และความดันควบคุม เพื่อกําจัดความชื้นจากวัสดุโดยรักษาความสมบูรณ์แบบโครงสร้างของพวกเขา กระบวนการนี้ที่รู้จักกันในชื่อการหล่อล้างน้ําแข็ง ทํางานโดยการแช่แข็งผลิตภัณฑ์ก่อน จากนั้นสร้างสภาพแวดล้อมว่างที่น้ําแข็งเปลี่ยนเป็นควายโดยตรง โดยไม่ผ่านช่วงของของเหลว ห้องว่างเป็นช่องหลักที่กระบวนการที่ซับซ้อนนี้เกิดขึ้น โดยมีระบบควบคุมอุณหภูมิที่แม่นยํา ระบบตรวจสอบความดัน และหน่วยประปาพิเศษ ห้องถูกออกแบบด้วยการสร้างเหล็กไร้ขัดแข็ง และโดยทั่วไปมีชั้นหลายชั้นสําหรับความจุในการแปรรูปสูงสุด เครื่องแห้งแบบแช่แข็งแบบว่างสมัยใหม่มีระบบควบคุมดิจิตอลที่ทันสมัยสําหรับการปรับปารามิเตอร์ ความสามารถในการบันทึกข้อมูล และการจัดการวงจรอัตโนมัติ เทคโนโลยีนี้พบการใช้งานที่กว้างขวางในอุตสาหกรรมต่างๆ รวมถึงการผลิตยา การแปรรูปอาหาร การวิจัยชีวเทคโนโลยี และวิทยาศาสตร์วัสดุ การ ที่ ระบบ นี้ สามารถ รักษา โครงสร้าง ภาพ และ คุณสมบัติ ทาง ชีวเคมี ของ ผลิตภัณฑ์ ได้ อย่าง เสมอ ทํา ให้ ระบบ นี้ มี คุณค่า ไม่ คุ้มค่า ในการ สร้าง ยา แบ็กซีน ที่ ใช้ ได้ ยาวนาน, การ รักษา ตัวอย่าง ของ อาหาร, การ ผล การบูรณาการของเซ็นเซอร์และระบบควบคุมที่ซับซ้อนจะทําให้ผลลัพธ์ที่ตรงกันและกันและความน่าเชื่อถือของกระบวนการ ในขณะที่การออกแบบห้องว่างจะอํานวยความสะดวกในการถ่ายทอดความร้อนและการกําจัดปืนที่มีประสิทธิภาพในระหว่างกระ