vacuum freeze drying equipment

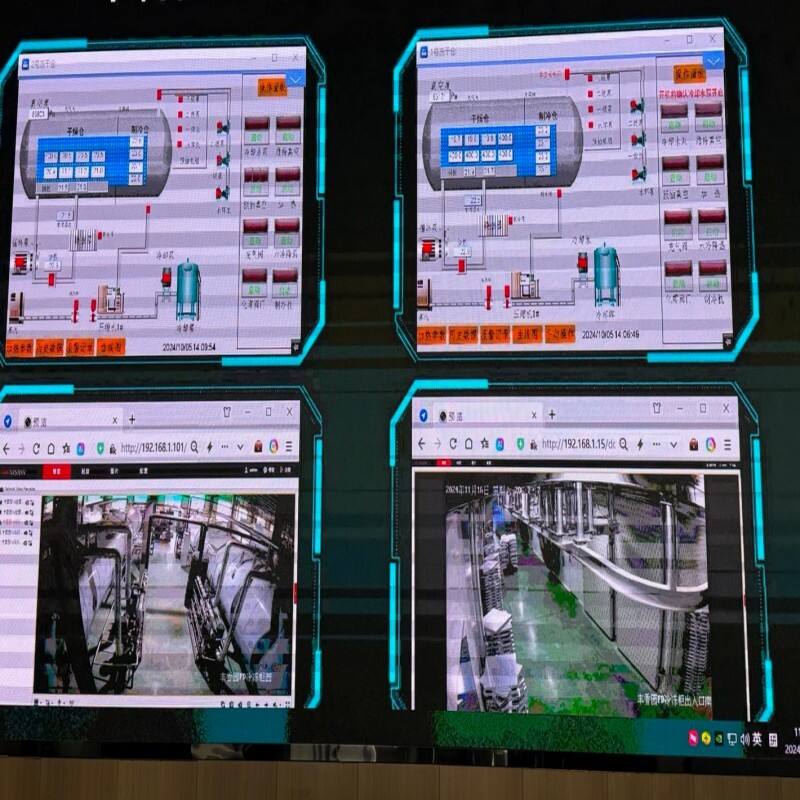

Vacuum freeze drying equipment represents a sophisticated solution for preserving materials through the process of lyophilization. This advanced technology removes moisture from substances by first freezing them and then creating a vacuum environment where ice directly transitions to vapor, bypassing the liquid phase. The equipment consists of several essential components including a freezing chamber, vacuum system, heating plates, and condensing unit. Operating at temperatures as low as -50°C and pressures below 0.1 mbar, this equipment ensures optimal preservation of product integrity. The system features precise temperature and pressure controls, programmable recipe management, and advanced monitoring capabilities for consistent results. Applications span across multiple industries, from food processing and pharmaceuticals to biotechnology and materials science. The equipment can handle various product formats including bulk materials, pre-filled vials, and delicate biological samples. Modern units incorporate energy-efficient designs, automated cleaning systems, and user-friendly interfaces for streamlined operation. The technology excels in maintaining product structure while achieving extremely low residual moisture content, typically below 1%. This makes it invaluable for preserving heat-sensitive materials and creating shelf-stable products that retain their original properties.