freeze dried snack processing equipment

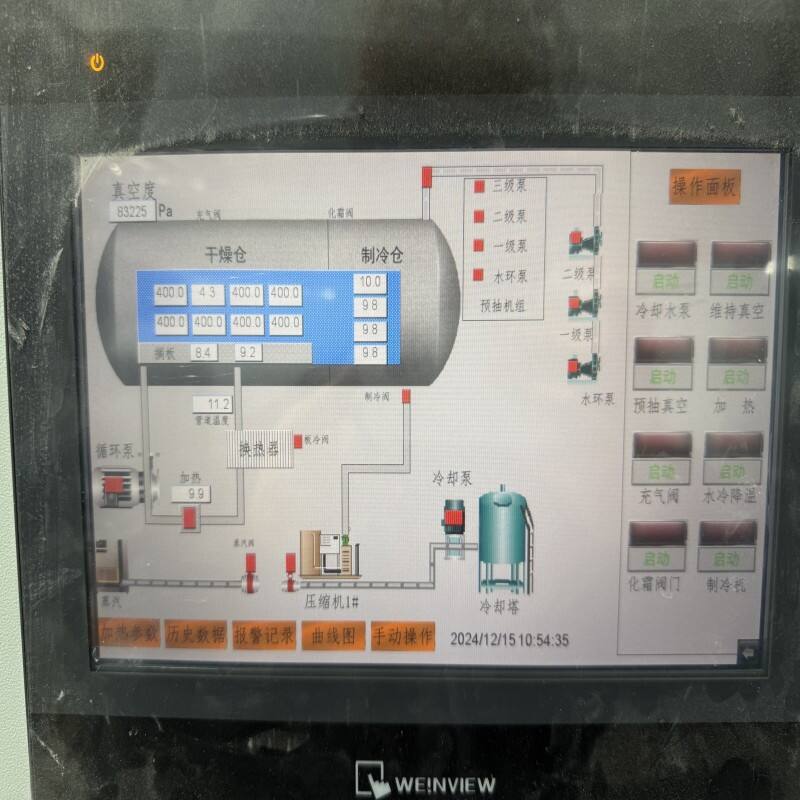

Freeze dried snack processing equipment represents a cutting-edge solution in modern food manufacturing, designed to produce high-quality, shelf-stable snacks while preserving their natural flavors, textures, and nutritional content. This sophisticated machinery operates through a precise sublimation process, where frozen products transition directly from solid ice to vapor, bypassing the liquid phase. The equipment typically consists of multiple integrated components, including freezing chambers, vacuum systems, heating elements, and control units that work in harmony to achieve optimal results. The system first rapidly freezes the raw materials at temperatures below -40°C, then creates a high-vacuum environment where controlled heat application facilitates the sublimation process. Advanced sensors and automated controls maintain precise temperature and pressure parameters throughout the process, ensuring consistent product quality. The equipment can process various food items, from fruits and vegetables to meat and dairy products, making it versatile for different snack applications. Modern units feature user-friendly interfaces, energy-efficient operations, and customizable programming options to accommodate different product specifications.