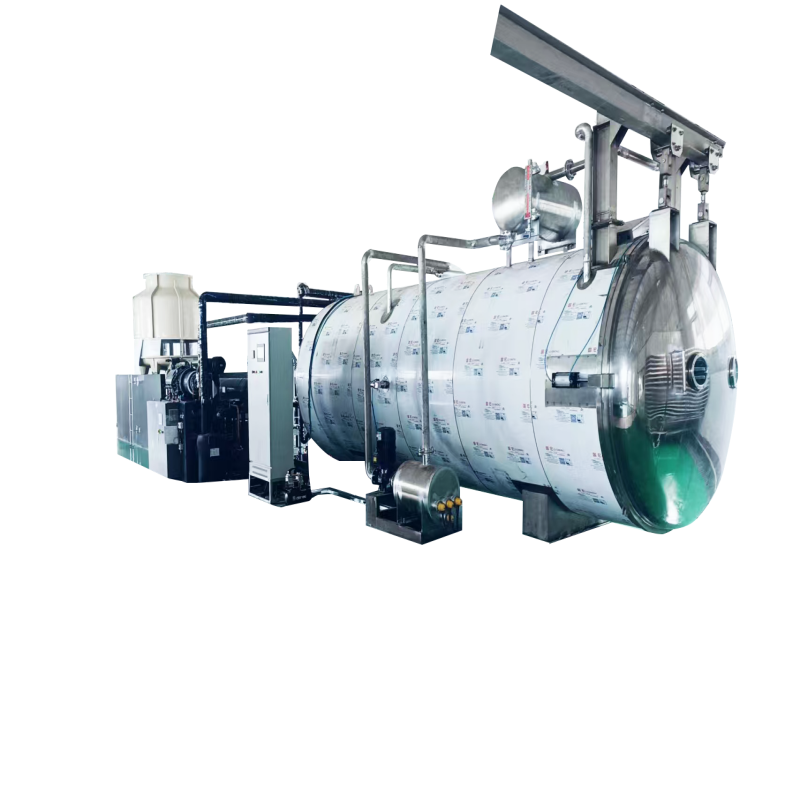

เครื่องทำให้แห้งแบบแช่แข็งอัตโนมัติ

เครื่องทำให้แห้งแบบแช่แข็งอัตโนมัติ (Automatic Lyophilizer Freeze Dryer) ถือเป็นนวัตกรรมชั้นสูงในเทคโนโลยีการถนอมรักษา ซึ่งรวมเอาความก้าวหน้าของระบบอัตโนมัติเข้ากับความสามารถในการทำให้แห้งแบบแช่แข็งอย่างแม่นยำ เครื่องจักรที่มีความซับซ้อนนี้ทำงานโดยการแช่แข็งวัสดุ จากนั้นลดความดันเพื่อให้น้ำแข็งเปลี่ยนสถานะจากของแข็งไปเป็นไอก๊าซโดยตรง โดยไม่ผ่านสถานะของเหลว ซึ่งเป็นกระบวนการที่เรียกว่าการระเหิด (Sublimation) ระบบดังกล่าวมีระบบควบคุมอัจฉริยะที่ช่วยรักษาสภาพอุณหภูมิและความดันให้เหมาะสมตลอดกระบวนการทั้งหมด เพื่อให้ได้ผลลัพธ์ที่มีคุณภาพสม่ำเสมอ เครื่องทำให้แห้งแบบแช่แข็งอัตโนมัตินี้มีเซ็นเซอร์วัดอุณหภูมิหลายจุด ระบบตรวจสอบความดันสุญญากาศ และระบบควบคุมแบบตั้งโปรแกรมได้ ซึ่งช่วยให้สามารถปรับรอบการอบแห้งให้เหมาะสมกับวัตถุตัวอย่างแต่ละชนิด ดีไซน์ที่ยืดหยุ่นสามารถรองรับขนาดและประเภทของตัวอย่างที่หลากหลาย ตั้งแต่ผลิตภัณฑ์เภสัชกรรม วัสดุชีวภาพ ไปจนถึงอาหารและตัวอย่างเพื่อการวิจัย อุปกรณ์นี้ประกอบด้วยระบบปั๊มสุญญากาศที่ทนทาน หน่วยทำความเย็นที่มีประสิทธิภาพ และชั้นวางที่ให้ความร้อนซึ่งช่วยกระจายอุณหภูมิอย่างทั่วถึง นอกจากนี้ คุณสมบัติด้านความปลอดภัยอย่างเช่น โหมดปิดเครื่องอัตโนมัติและการแจ้งเตือนของระบบ ยังช่วยให้การทำงานมีความน่าเชื่อถือ ในขณะที่อินเตอร์เฟซที่ใช้งานง่ายช่วยให้ผู้ใช้สามารถตรวจสอบและปรับตั้งค่าต่าง ๆ ได้อย่างสะดวก เทคโนโลยีนี้มีความสำคัญอย่างยิ่งในหลายอุตสาหกรรม เช่น การผลิตยา การแปรรูปอาหาร การวิจัยทางเทคโนโลยีชีวภาพ และวิทยาศาสตร์วัสดุ ซึ่งการรักษาคุณภาพของผลิตภัณฑ์ไว้ให้ได้มากที่สุดในระหว่างการเก็บรักษาเป็นสิ่งจำเป็น