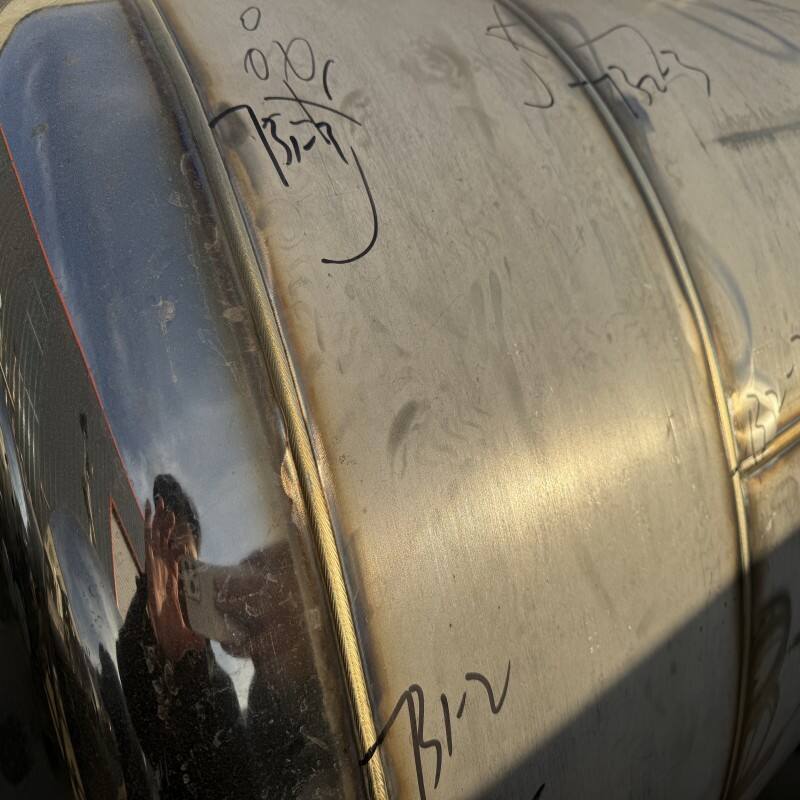

vacuum freeze drying systems

Vacuum freeze drying systems represent a sophisticated method of preservation that combines the principles of vacuum technology and sublimation to remove moisture from materials while maintaining their structural integrity and essential properties. These advanced systems operate by freezing the product and then reducing pressure to allow frozen water to transition directly from solid to vapor state, bypassing the liquid phase. The process involves three main stages: freezing, primary drying (sublimation), and secondary drying (desorption). The technology utilizes precise temperature control, pressure manipulation, and advanced sensor systems to ensure optimal processing conditions. Modern vacuum freeze drying systems incorporate automated controls, energy-efficient components, and sophisticated monitoring capabilities to maintain product quality throughout the process. These systems find widespread applications across various industries, including pharmaceuticals, food processing, biotechnology, and materials science. The equipment can handle diverse materials ranging from food products and biological samples to pharmaceuticals and heat-sensitive compounds. The systems are designed with features such as programmable recipe management, data logging capabilities, and validation protocols to ensure consistent and reliable performance.