industrial fruit dehydrator machine

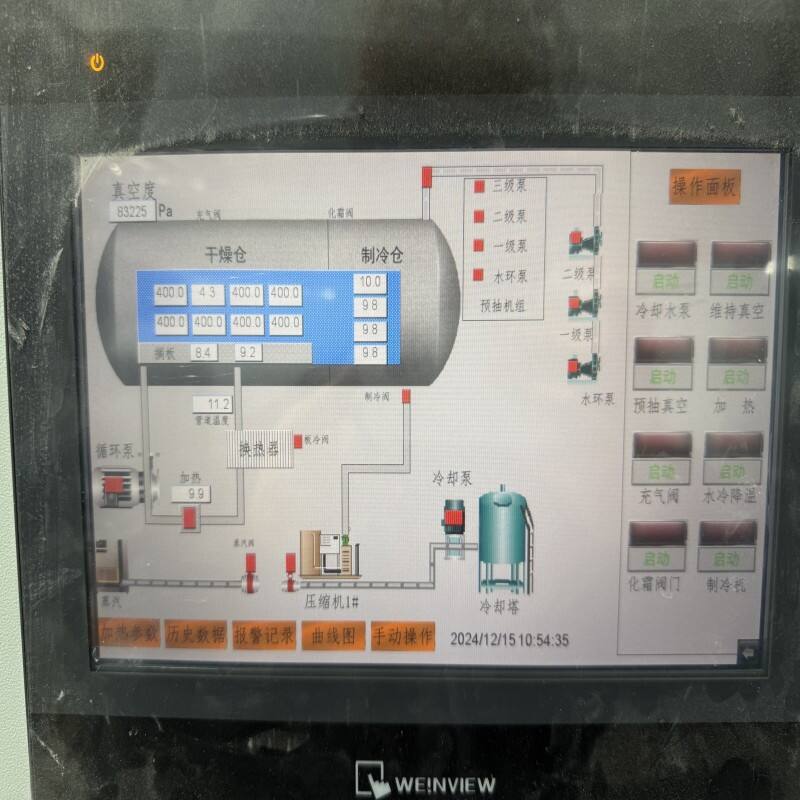

The industrial fruit dehydrator machine represents a cutting-edge solution for commercial food processing, designed to efficiently remove moisture from various fruits while preserving their essential nutrients and flavors. This sophisticated equipment utilizes advanced temperature control systems and precision airflow technology to ensure consistent drying results across multiple layers of product. The machine features adjustable temperature settings ranging from 95°F to 165°F, allowing operators to customize drying parameters for different types of fruits. Built with food-grade stainless steel components, these dehydrators incorporate multiple drying chambers with rotating trays that promote uniform air circulation. The system's intelligent moisture sensors continuously monitor and adjust the drying process, preventing over-drying while maintaining optimal product quality. These machines can process hundreds of pounds of fresh fruit per cycle, making them ideal for large-scale food production facilities, agricultural processing centers, and commercial dried fruit manufacturers. The digital control panel enables precise management of time, temperature, and humidity levels, while the energy-efficient design minimizes operational costs without compromising performance.