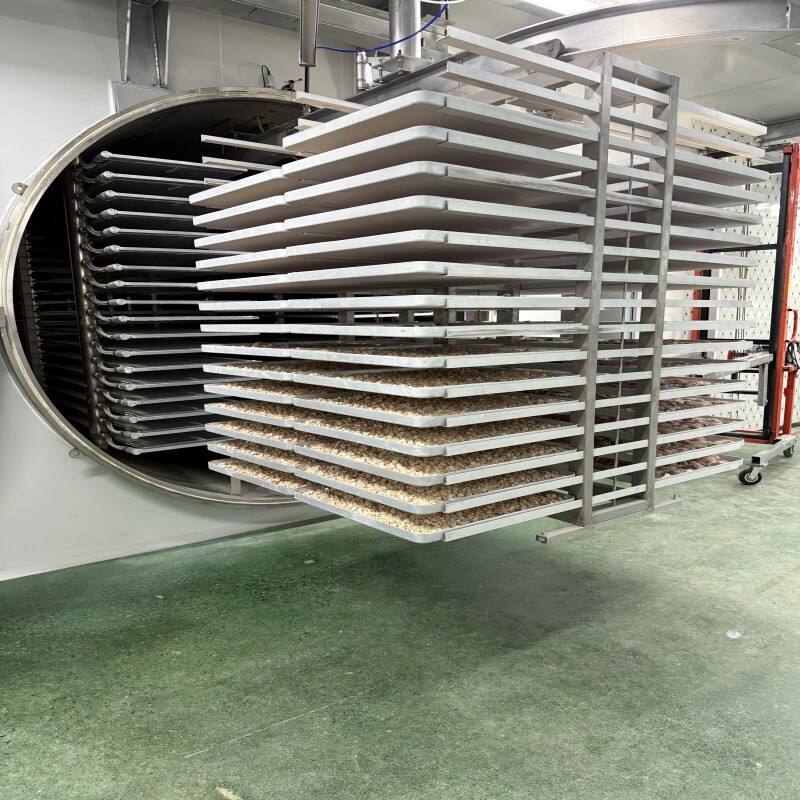

industrial drying oven

Industrial drying ovens are sophisticated thermal processing equipment designed to remove moisture from materials and products through controlled heating and air circulation. These versatile units operate by maintaining precise temperature control and uniform heat distribution, typically ranging from 40°C to 500°C, depending on the specific model and application requirements. The systems incorporate advanced airflow technology, featuring forced air circulation that ensures even heat distribution and efficient moisture removal. Modern industrial drying ovens come equipped with programmable controls, allowing operators to set specific temperature profiles, timing sequences, and ventilation parameters. These ovens are constructed with high-grade materials, including stainless steel chambers and superior insulation, ensuring durability and energy efficiency. They often feature multiple shelving configurations, adjustable air intake and exhaust systems, and advanced safety mechanisms including overtemperature protection and emergency shutoff systems. The applications span across numerous industries, including manufacturing, electronics, pharmaceuticals, and research facilities, where they are used for processes such as curing, heat treating, aging, and sterilization. The ovens can accommodate various batch sizes and can be customized with additional features such as data logging capabilities, remote monitoring systems, and specialized loading mechanisms.