vacuum freeze dryer price

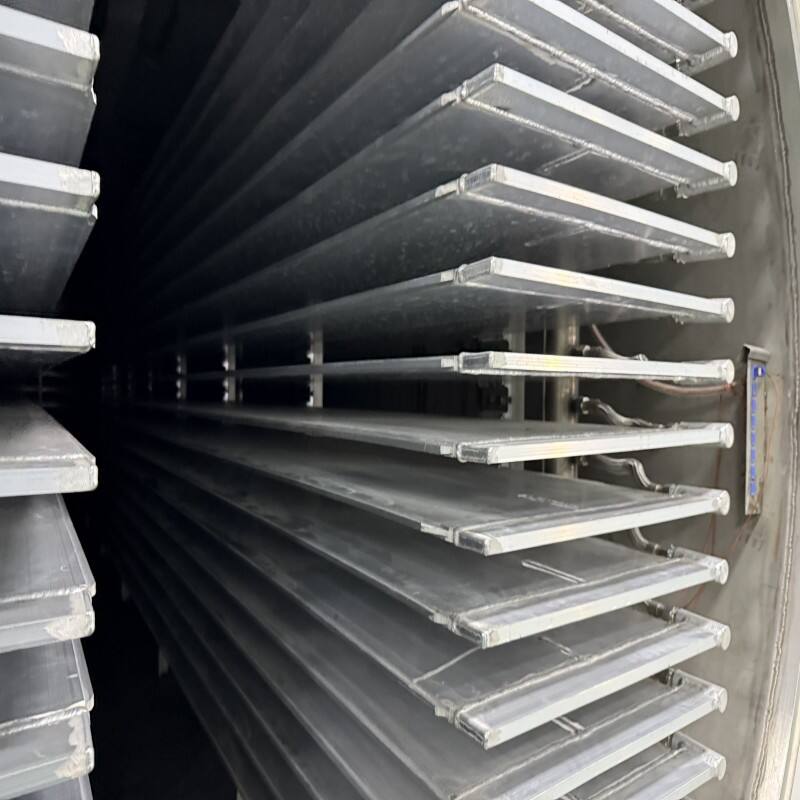

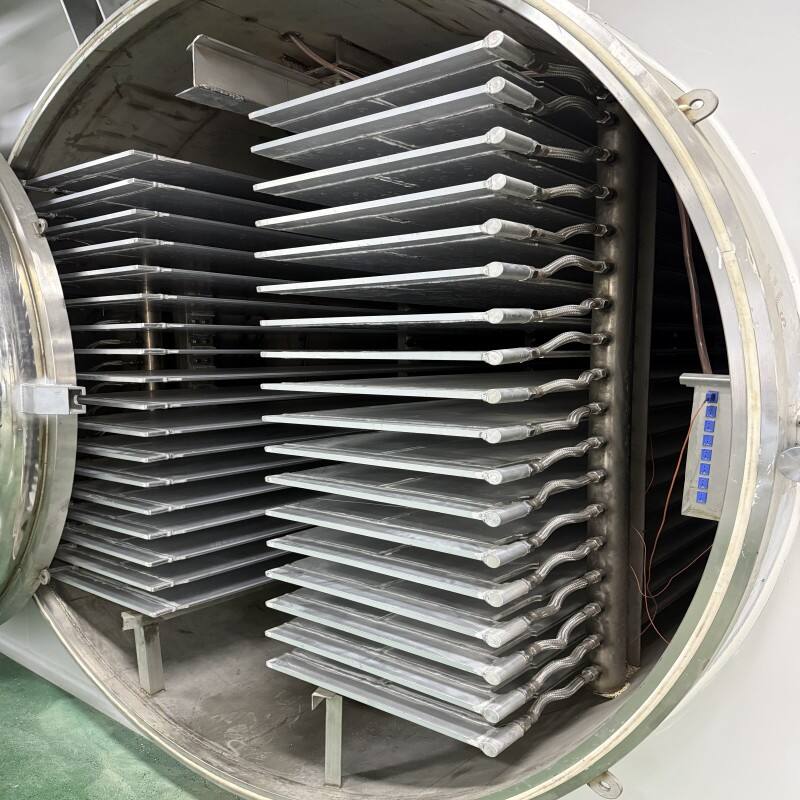

The vacuum freeze dryer price reflects the sophisticated technology and versatility of this essential processing equipment. Modern vacuum freeze dryers combine advanced freezing techniques with precise vacuum control systems, offering a comprehensive solution for preserving sensitive materials. These units typically range from $5,000 for small laboratory models to $50,000 or more for industrial-scale equipment. The price variation depends on factors such as chamber size, automation level, and additional features. These systems operate by freezing products at extremely low temperatures, then removing moisture through sublimation under vacuum conditions. The technology maintains product integrity by preserving structure, flavor, and nutritional content. Applications span across pharmaceutical, food processing, biotechnology, and research sectors. The investment includes core components like vacuum pumps, refrigeration systems, heating elements, and digital control interfaces. Many manufacturers offer customizable options, allowing buyers to select features based on their specific needs and budget constraints. The price point also typically covers installation, training, and initial technical support, ensuring optimal system performance from day one.