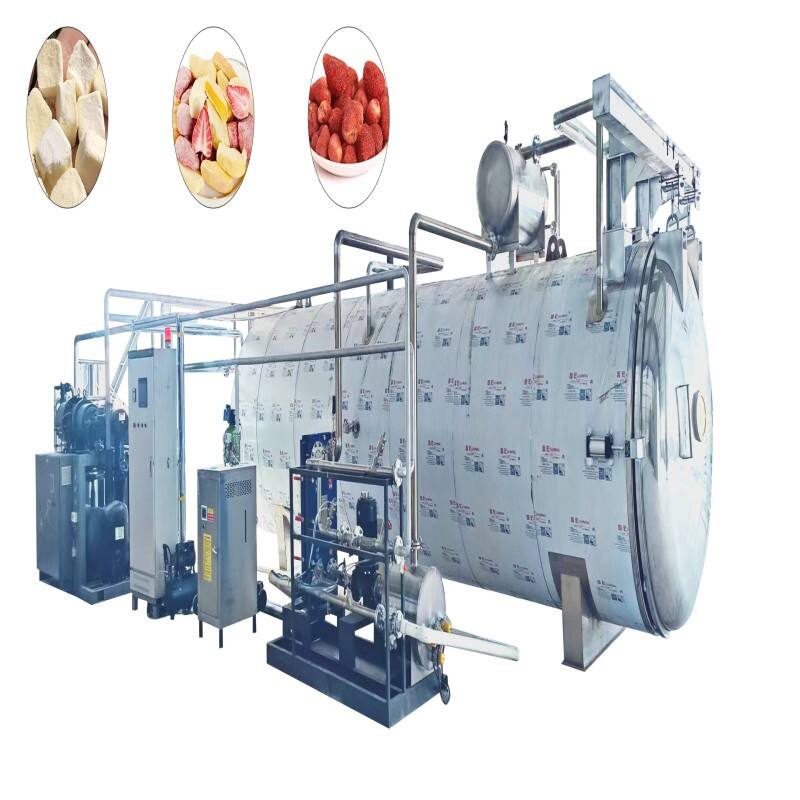

freeze dryer lyophilizer for sale

A freeze dryer lyophilizer represents cutting-edge technology in preservation and processing equipment, designed to remove moisture from various materials while maintaining their structural integrity and essential properties. This sophisticated system operates through a precise sublimation process, converting frozen water directly into vapor without passing through a liquid phase. The equipment features advanced temperature control systems, ranging from -50°C to -80°C, coupled with powerful vacuum technology that maintains pressures as low as 10 Pa. The system incorporates multiple temperature-controlled shelves, allowing for simultaneous processing of different batches. Modern freeze dryer lyophilizers come equipped with intuitive touch-screen interfaces, programmable cycle parameters, and real-time monitoring capabilities. These units are available in various sizes, from benchtop models suitable for laboratory research to industrial-scale systems for commercial production. The technology finds extensive applications across pharmaceutical, biotechnology, food processing, and research sectors, offering precise control over the preservation process while ensuring product quality and stability.