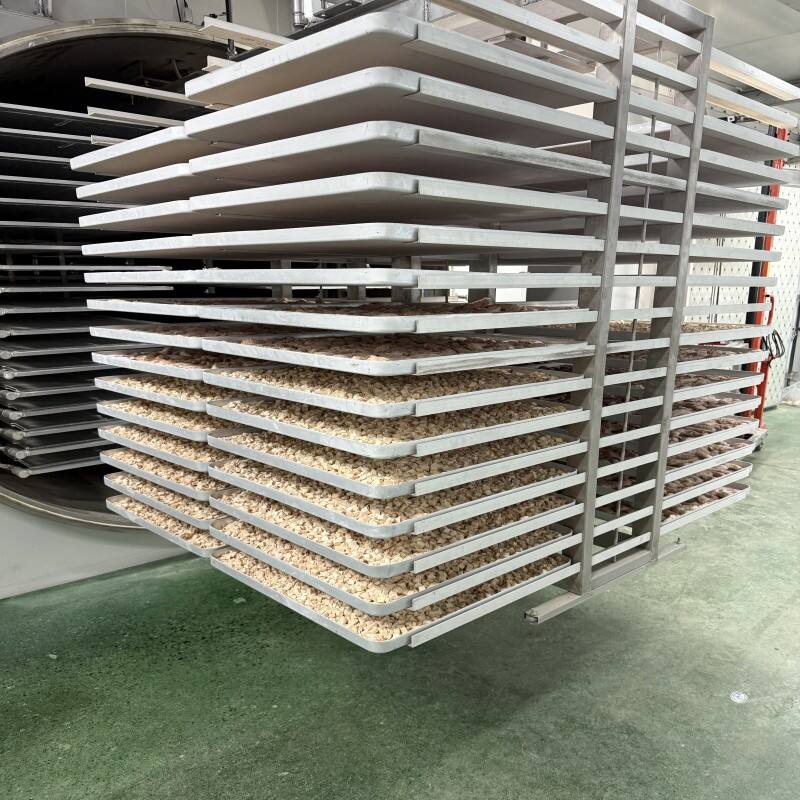

vacuum freeze dryer for sale

The vacuum freeze dryer represents a cutting-edge solution for preserving materials through the sophisticated process of lyophilization. This advanced equipment operates by freezing products and then reducing pressure to allow frozen water to transform directly from solid to vapor, bypassing the liquid phase. The system features precision temperature controls ranging from -50°C to +70°C, maintaining optimal conditions throughout the drying cycle. Equipped with high-performance vacuum pumps capable of achieving pressures below 10 Pa, these units ensure thorough moisture removal while preserving the product's original structure and properties. The freeze dryer's intelligent control system monitors and adjusts parameters in real-time, offering both automatic and manual operation modes for maximum flexibility. Available in various capacities from laboratory to industrial scale, these units accommodate diverse applications including food preservation, pharmaceutical processing, and biotechnology research. The condensing system efficiently captures removed moisture, while the heating system provides carefully controlled energy input for sublimation. Multiple temperature sensors and pressure gauges ensure precise monitoring throughout the process, while the user-friendly interface displays critical parameters and allows for easy adjustment of operating conditions.